Aluminium Filtration System

“An indispensible system to

guarantee the quality and uninterrupted

production of high quality aluminum”

METALOFILTER® PTF (Porous Tube Filter)

Upon first introducing and proving its‘ practical uses in Japan, Mitsui Kinzoku’s METALOFILTER® system quickly gained interest and became the leading molten aluminum filter system in the Japanese aluminum industry and currently maintains over 90% market share to date. Since its initial success in Japan, METALOFILTER® has also gained recognition worldwide with more than 500 units being comissioned due to its highly efficient filtering capabilities.

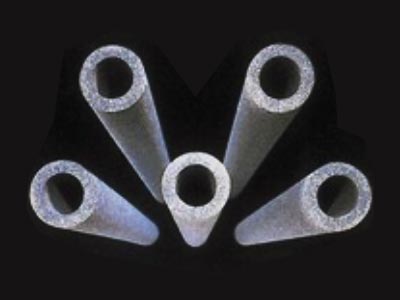

Filter tubes

Molten aluminum metal is filtered through porous tubes made of fused, regulated alumina. There are several tube grades (listed below), categorized according to a tightly controlled ceramic grain size for each grade, to achieve the desired inclusion size removal.

Filter tubes grades

RAA

General Materials, such as construction and many other applications

30 μm Consistenly Removable Particle/Inclusion Size

RB

Can Body Stock/ Wheels

20 μm Consistenly Removable Particle / Inclusion Size

RC

Can body Stock / Foils

10 μm Consistenly Removable Particle / Inclusion Size

RD

Can Body Stock Copier drums / foils

5 μm Consistenly Removable Particle / Inclusion Size

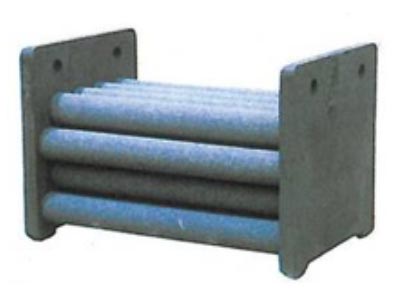

Cartridge

The filter tubes are assembled in a cartridge for easy installation and removal. The number of tubes per cartridge ranges from 7 to 28 tubes depending on customer capacity requirements.

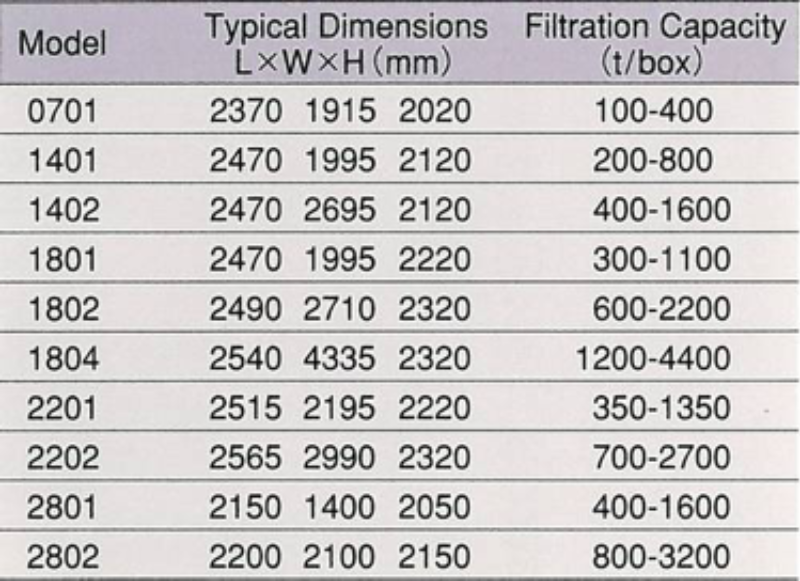

Specifications

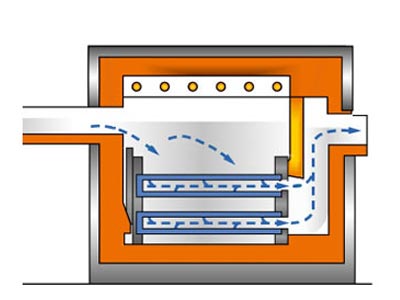

There are several filtering box sizes available depending on the customer filtration capacity requirements. Boxes are constructed of (EU) S235JR / (JPN) SS400 grade steel and lined with very high quality/long lasting Si3N4 bonded SiC refractories.

SiC heating elements to preheat the box and/or to maintain molten metal temperature are installed in the lid of the box. The Control panel uses our standard PLC and touchscreen, but in many cases we can also install a PLC from a manufacturer requested by the customer. The unit incorporates alarms for abnormal molten metal temperature, current leakage, over-current and abnormal thyristor status. The system also produces and stores graphical data displaying the heating curves achieved for later reference and quality control.