Hi-Cera SN Series (Si3N4)

Hi-Cera SN

We offer four types of Si3N4 materials, Hi-cera SN-A1, SN-A2, SN-B1, SN-B2. Their development was based on the following criteria:

- Hi-Cera SN-A2: Improved bending strength

- Hi-Cera SN-B1: Improved thermal conductivity

- Hi-Cera SN-B2: Improved bending strength and thermal conductivity

Material

Silicon Nitride advanced ceramics (Si3N4)

Characteristics

Excellent heat shock resistance, corrosion resistance to molten aluminum alloys, and high wear resistance.

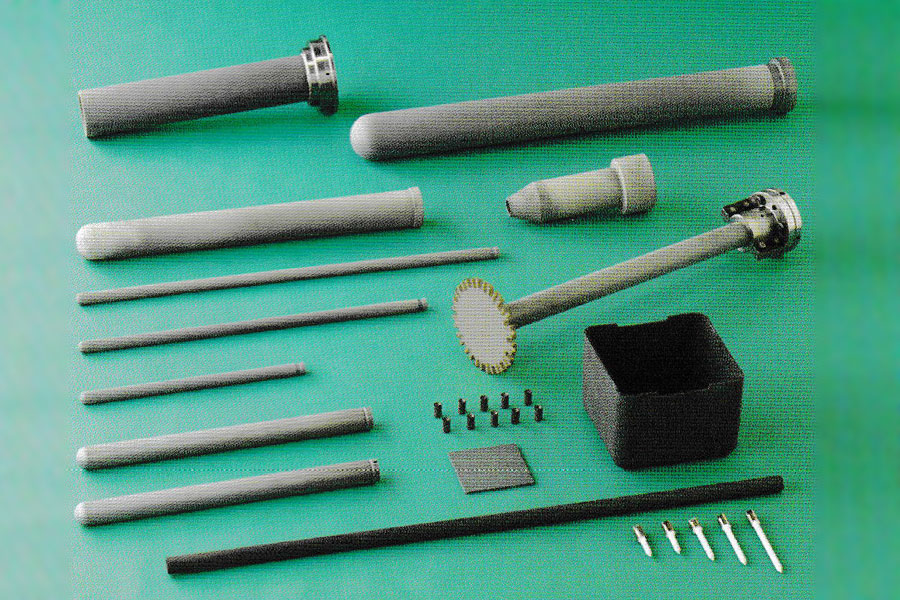

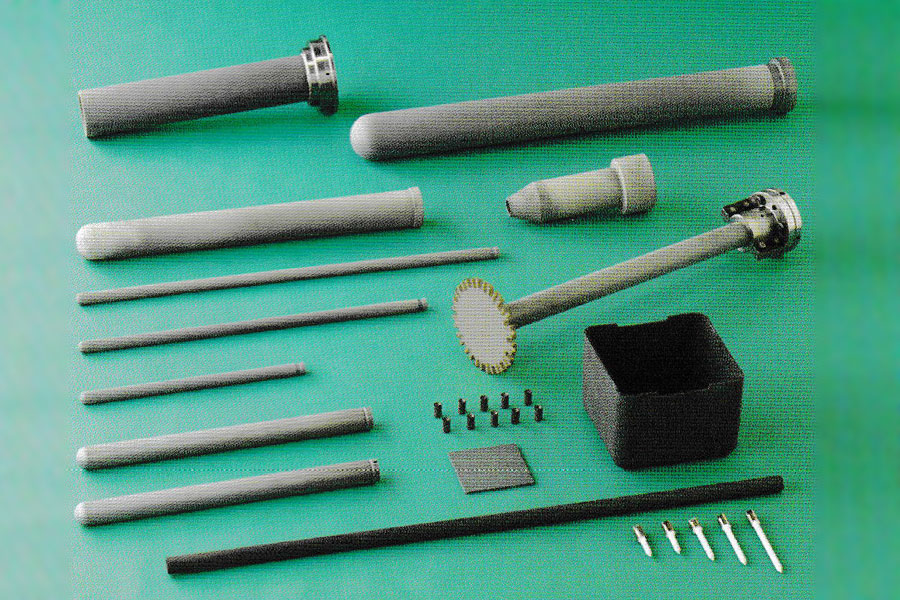

Applications

Protection tubes, heater tubes, degassing rotors as well as additional parts for treating molten aluminum.

Datasheet available upon request

Hi-Cera SN-A1

This (Si3N4) material is used in components for Al melting furnaces such as heater tubes, protective tubes and burner nozzles.

Datasheet available upon request

Hi-Cera SN-B1

This (Si3N4) material is typically used for stalks/riser tubes in low pressure Aluminum casting processes and for the degassing rotor parts in Aluminum continuous die-casting, due to its advantages in terms of thermal-shock resistance and mechanical strength.

Datasheet available upon request

Hi-Cera SN-B2

This (Si3N4) material is typically used in the impeller of degassing rotors for automotive applications, due to it‘s improved shock resistance and mechanical strength.

Datasheet available upon request