Contributing

to steel’s future

Technology

Since the introduction of the Rhesca - later Iwatani Surtec - now SURTEC RESEARCH HDP Simulator almost 40 years ago, steel producers have increasingly advanced the technology of continuously annealed and coated sheet products to meet the challenges of automotive and appliance manufacturers. Following a continuous strategy of innovation ensures sustainable advantage in the market, reflecting the depth of your know-how in processing and the creativity of your product development.

Production know-how can either be licensed with significant license fees and royalties or developed in-house by your own investment in R&D expertise and facilities.

The right choice depends on your basic strategic decisions and will be of significant importance for your company and its competitiveness. What we have observed over the years is a continuous trend towards independent R&D / Product Development all over the world. The increasing demand for our SURTEC RESEARCH Simulators may be seen as proof of this trend.

Should you decide to improve and further develop your production know-how independently you require universal knowledge about material development and its property influences. Product properties are influenced by multiple parameters in each process zone of CA and CG Lines, such that specifying the proper heating, pre-oxidation, soaking, cooling, transformation, dipping, wiping and galvannealing conditions requires a reliable method of process parameter verification. Validation on production or pilot lines is neither economical nor efficient. Validation by laboratory scale process simulation however has been recognized to be the most economical, efficient and reliable method along with great time-to-market advantages.

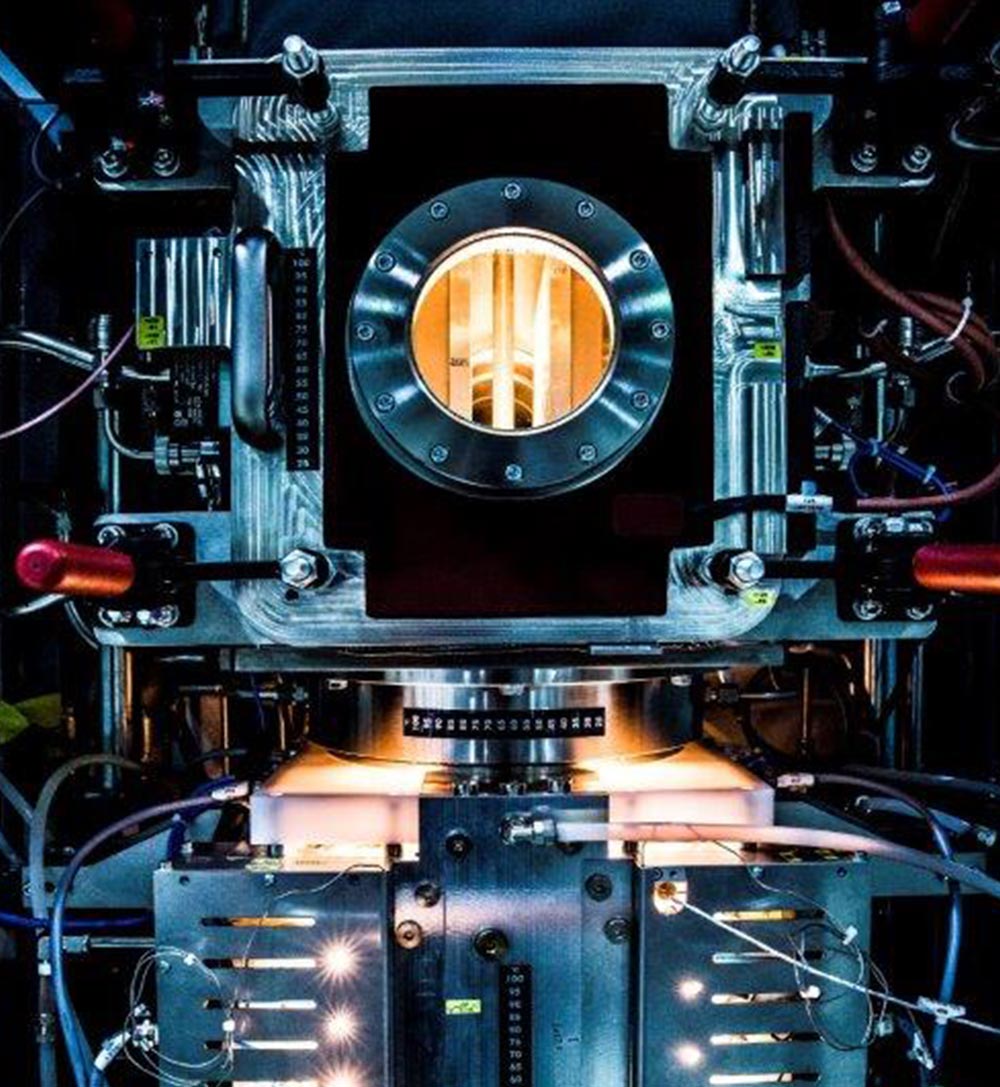

SURTEC RESEARCH Multifunctional HDAPS Simulators are specially designed to cope with the latest challenging requirements of innovative thermal treatment cycles of high alloyed steel grades such as AHS- and UHS steels, as well as Si-Steels.

Thanks to their unique and very precise heating and cooling capabilities as well as accurate atmospheric (process) gas and dew point control our simulators allow almost unlimited Research and Development of mechanical (and electrical) properties and surface/subsurface conditioning.

Producers of structural automotive steels increasingly need to exploit all metallurgical concepts in optimizing material deformation behavior for excellent formability and energy absorption. This implies exploitation of heating and very fast cooling rates that result in novel microstructures through conventional recrystallization and transformation processes and increasingly via non-equilibrium effects creating fine scale metastable structures and diffusion enriched phases. Of increasing interest in this field is the additional potential for surface reactions to generate graded compositions with novel mechanical and tribological characteristics.

Si-Steel product development plays a key role in tailoring core loss and permeability characteristics of magnetic materials for the range technological applications in power distribution, rotating machinery or high frequency applications. Surface reaction control also participates in developing the appropriate composition and microstructure while stress annealing concepts can be explored as an optimization strategy.

For any material development project the size-scale of simulation is an important consideration that relates to the ability to perform meaningful evaluation tests. SURTEC RESEARCH Simulators provide users with test sheet dimensions having the uniformity characteristics that permit direct utilization of material in most standardized tests.

Beyond the state-of the-art lies the next generation of value added products and innovative processes to make them. The SURTEC RESEARCH HDP Simulator has evolved with need to become the world standard for annealing and galvanizing simulation. More than 65 units at top steel companies and universities are currently contributing to steel’s future.

Main Characteristics of all SURTEC RESEARCH Simulators

- Realistic Simulation of Annealing, Galvanizing and Galvannealing Processes in a Laboratory Scale

- Simulation Results transferrable to your CA and CGL Production Process / Production Lines

- Huge Variability of Parameters (i.e. Gas Atmospheres, Humidity, Heating & Cooling Rates, Process Sequences, Bath Chemistries & Temperatures)

- Individually configurable thanks to the Multifunctional Modular Concept