Industrial Process Simulation & Analysis

SURTEC RESEARCH Simulators are research equipment, which allow laboratory scale simulation of (reactive) annealing and (hot dip) coating processes occurring in production lines. The simulators serve for process improvement and new product development; the optimized thermal treatment and coating parameters obtained by simulation can be transferred to the production process in your existing Continuous Annealing (CA) and Galvanizing / Galvannealing Lines (GI/GA).

All important functions of the production process such as cleaning, thermal treatment (heating up, soaking, cooling), hot dip coating (Zn, Al, Si, Mg, etc.), galvannealing, etc. can be simulated in a laboratory scale. The consumption of operating materials is extremely small compared with mini- or production lines and valuable production capacities do not need to be wasted.

SURTEC RESEARCH Simulators anneal and coat steel samples of desirable higher strength to determine the optimum process parameters for the production lines. New products with improved coatings, new coating technologies, modified thermal treatments and process sequences can be tested at very low cost and in a very short time. All SURTEC RESEARCH Simulators are built in compliance with the latest applicable European Safety Standards, i.e. CE and ATEX.

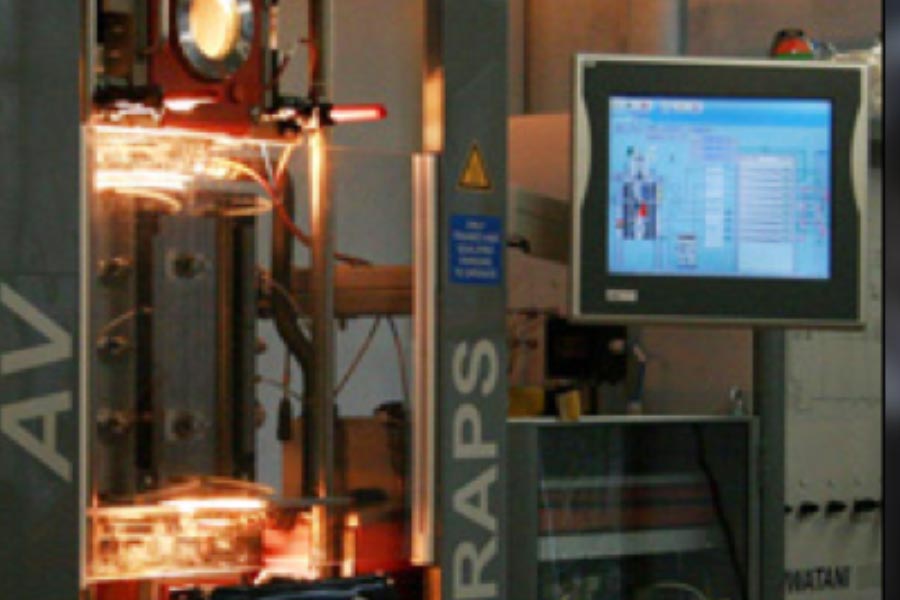

TYPE 1

Reactive Annealing Process Simulator (RAPS)

Laboratory Scale Simulation of Annealing Processes, Controlled heating, gas cooling, rapid gas cooling, quenching, water jet cooling, Gas atmospheres precisely controllable, Typical gases N2, H2, CO/CO2, NH3, H2O (dew point -60° C to +70°C)

For more details contact us!

TYPE 2

XTREME Annealing Simulator

(under development)

Big Size Specimen / Multifunctional Thermal Treatment Simulator

TYPE 3

Hot Dip Process Simulator

(HDPS)

Laboratory Scale Simulation of Annealing + Hot Dip Galvanizing, Galvannealing and Aluminizing

Basic Version

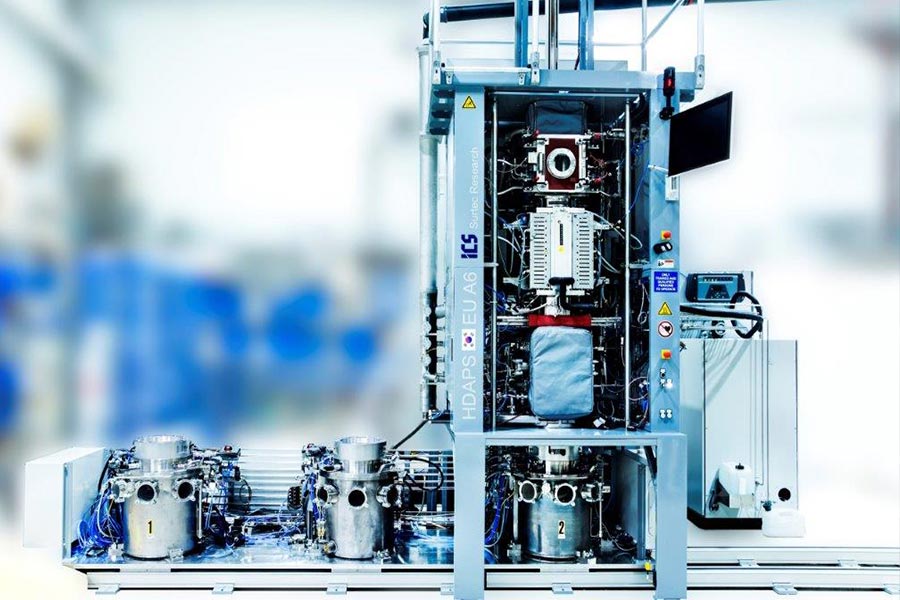

TYPE 4

Multi Funktional Hot Dip & Annealing Process Simulator

(HDAP-MF Simulator)

same as HDPS, but extended simulation capability / Product development for advanced automotive steels (A&UHSS) as well as SI-Steels (Generation V), Generation VI: with Multi-Bath System, with big sample option

Optionally available with several analytical modules, i.e.

- In-Situ Gas-Metal Reaction Analysis Module (TIM)

- In-Situ Oxide Layer Thickness Measurement (OLTM)

Generation VI: same as above, but with Multi-Bath System option, with Big Sample Option

For more details contact us!

TYPE 5

DFF-RTF Process Simulator

Laboratory Scale Simulation of Annealing, Preheat and pre-oxidation in a miniaturized Direct Fired Furnace (DFF), Soaking in an IR Furnace (RTF), Optional Hot Dip Galvanizing, Galvannealing and Aluminizing Module

For more details contact us!

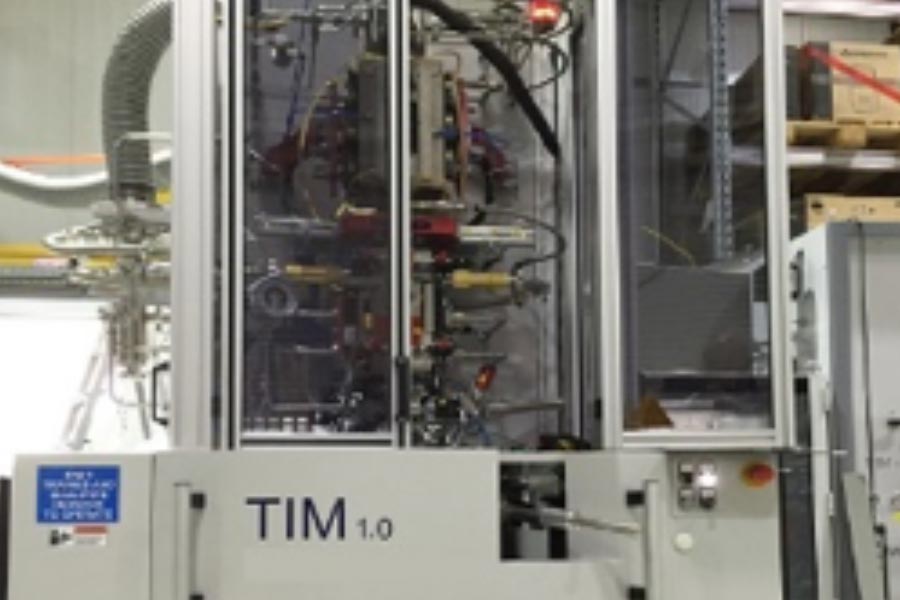

TYPE 6

TIM Analytical Process Simulator

Miniature Scale Simulation of Annealing Processes with In-Situ Gas-Metal Reaction Analysis (TIM), Molten Metal Bath and optional In-Situ Oxide Layer Thickness Measurement (OLTM)

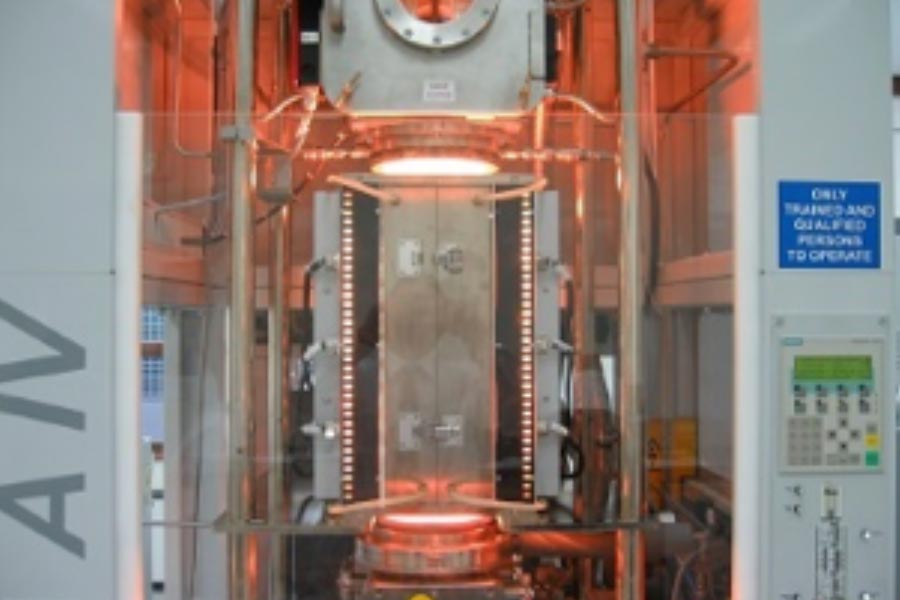

SURTEC RESEARCH Simulators are divided into 5 functional units

-

MAIN UNIT

Upper Chamber with the thermal treatment chambers including the functions- Annealing

- Soaking

- Cooling, incl. Super Fast Cooling for Q&P

- Inductive Heating

- Molten Metal Bath(s)

- Dross Removing System

- Guide Roll System

- Gas Wiping

- Touch Sensor

- GAS MIXING STATION

- HUMIDIFICATION STATION

- SAMPLE DRIVING Mechanism

- SYSTEM CONTROL

SURTEC RESEARCH is committed to continuous product development.

Highlights